WEARABLE TECH

This past summer, The Mill created a position for me in the Emerging Tech department. With my filmmaking background and current masters program at ITP, I was one of the few people who fit both fields combined. But The Mill is a critically acclaimed commercial production company and VFX house. They did not need more 3D modelers or Unreal Engine experts. The lead developer wanted my physical computing skills and the creative director was very focused on biometric feedback. They asked me to figure out their circuitry and housing — basically, how can I put all of these sensors onto people? And so began my interest in wearables.

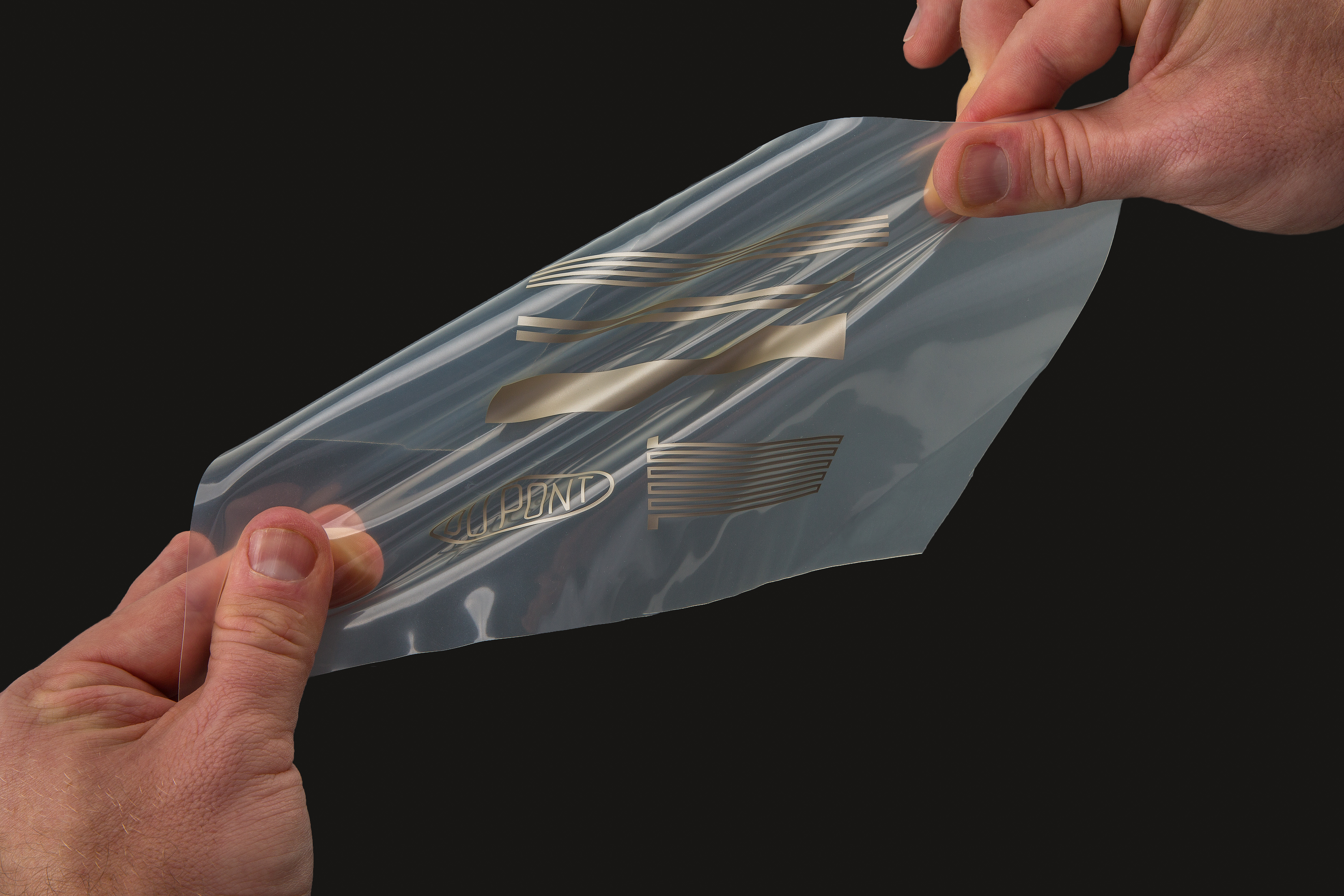

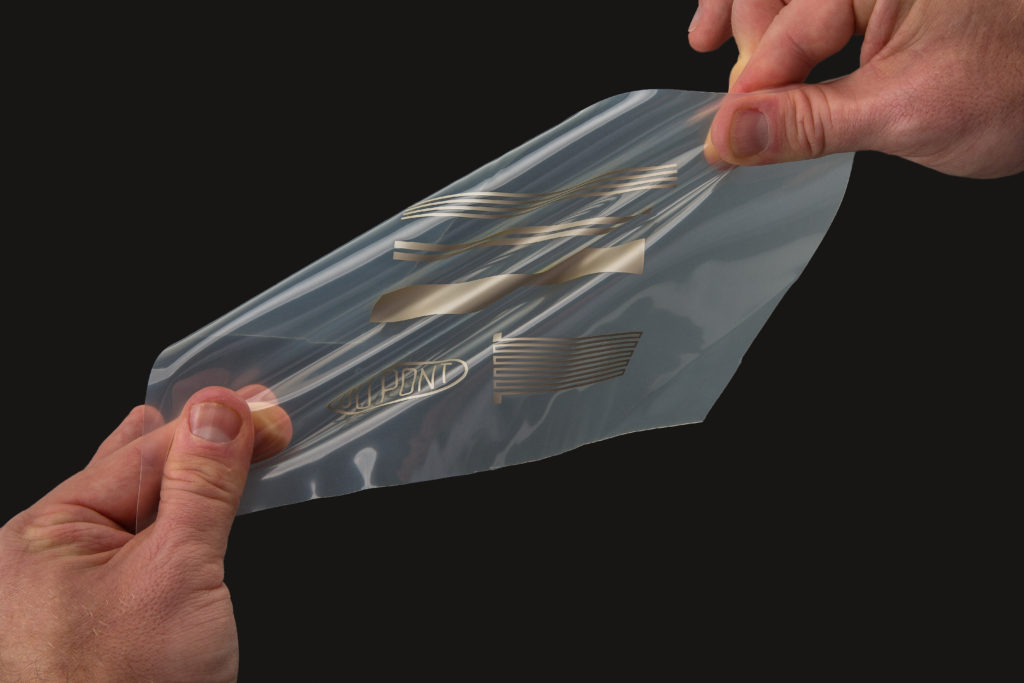

Since I had to consider a lot of problems like movement, comfort and creating wearable items that could fit different sized users, I really started to explore what goes into wearable technology. I taught myself to sew, spent a lot of time in the fashion district and began my first steps into materials research. The trip to Material Connexion was like a visit to the candy store! The entire conductivity aisle made my head explode with ideas. I landed on the Dupont printable ink for multiple reasons. It looked like it could help me with many wearable projects. And I knew that a company like Dupont would probably have great data sheets.

SOFT DUROMETER/FLEXIBILITY/ELASTICITY

From what I can gather, the stretchable ink can be used on many different fabrics so the soft durometer rating would probably be somewhat based on the fabric of choice. Since it was created for wearable technology to be worn on the human body, I would classify it as a soft material. It is also a flexible material because it is designed to move in every way wearable fabrics can move. The example at Material Connexion was similar to the image above. It was printed onto a very flexible piece of what I think is Polyurethane. And lastly, elasticity. The inks are named stretchable inks and therefore advertise this exact quality. The data sheets claim it is stretchable with a “trace width & strain relief design can enable >15% strain and 4% oscillating strain with minimal change in resistance.”

DISTRIBUTORS

Dupont is the manufacturer and after calling them, I believed they distribute directly. On my first call, I was forced to leave a message. A woman, Katie Smith called me back with questions about my interest in the product. It is her job to decide who within the company can assist me best in the next call or email. I explained I am a masters student and would love a sample. Katie took down all of my information and the answers to the few questions she asked. She informed me I would probably hear back in the next week or two. In case I do not, she gave me her phone number. Hopefully I will be able to get a free sample. Katie also informed me it is sold in both grams and kilograms, but could not give me pricing. A few hours later, I received an email from their distributor, Insulectro, requesting a call back to discuss further my needs so he can be sure to make the correct recommendations for my projects.

ON LABEL USE

(From the data sheet)

DuPont is introducing a stretchable ink suite for the wearables market

• Manufacturing-ready solution for smart clothing enabled by electronic inks – Thin and comfortable – Washable up to 100 cycles – Stable through repeated elongation

• Screen print formulations as needed for high volume and low cost

• Material selection guidance and post-sales support available

• Currently engaging commercial partners to expand wearable market development